[ad_1]

Each time you easily drive from level A to level B, you are not simply having fun with the comfort of your automotive, but additionally the subtle engineering that makes it protected and dependable. Past its consolation and protecting options lies a lesser-known but essential facet: the expertly optimized mechanical efficiency of microstructured supplies. These supplies, integral but typically unacknowledged, are what fortify your automobile, making certain sturdiness and energy on each journey.

Fortunately, MIT Laptop Science and Synthetic Intelligence Laboratory (CSAIL) scientists have thought of this for you. A staff of researchers moved past conventional trial-and-error strategies to create supplies with extraordinary efficiency by computational design. Their new system integrates bodily experiments, physics-based simulations, and neural networks to navigate the discrepancies typically discovered between theoretical fashions and sensible outcomes. Some of the hanging outcomes: the invention of microstructured composites — utilized in the whole lot from automobiles to airplanes — which are a lot more durable and sturdy, with an optimum stability of stiffness and toughness.

“Composite design and fabrication is prime to engineering. The implications of our work will hopefully prolong far past the realm of strong mechanics. Our methodology supplies a blueprint for a computational design that may be tailored to various fields equivalent to polymer chemistry, fluid dynamics, meteorology, and even robotics,” says Beichen Li, an MIT PhD scholar in electrical engineering and laptop science, CSAIL affiliate, and lead researcher on the venture.

An open-access paper on the work was revealed in Science Advances earlier this month.

Within the vibrant world of supplies science, atoms and molecules are like tiny architects, consistently collaborating to construct the way forward for the whole lot. Nonetheless, every aspect should discover its excellent companion, and on this case, the main target was on discovering a stability between two important properties of supplies: stiffness and toughness. Their technique concerned a big design area of two kinds of base supplies — one arduous and brittle, the opposite gentle and ductile — to discover varied spatial preparations to find optimum microstructures.

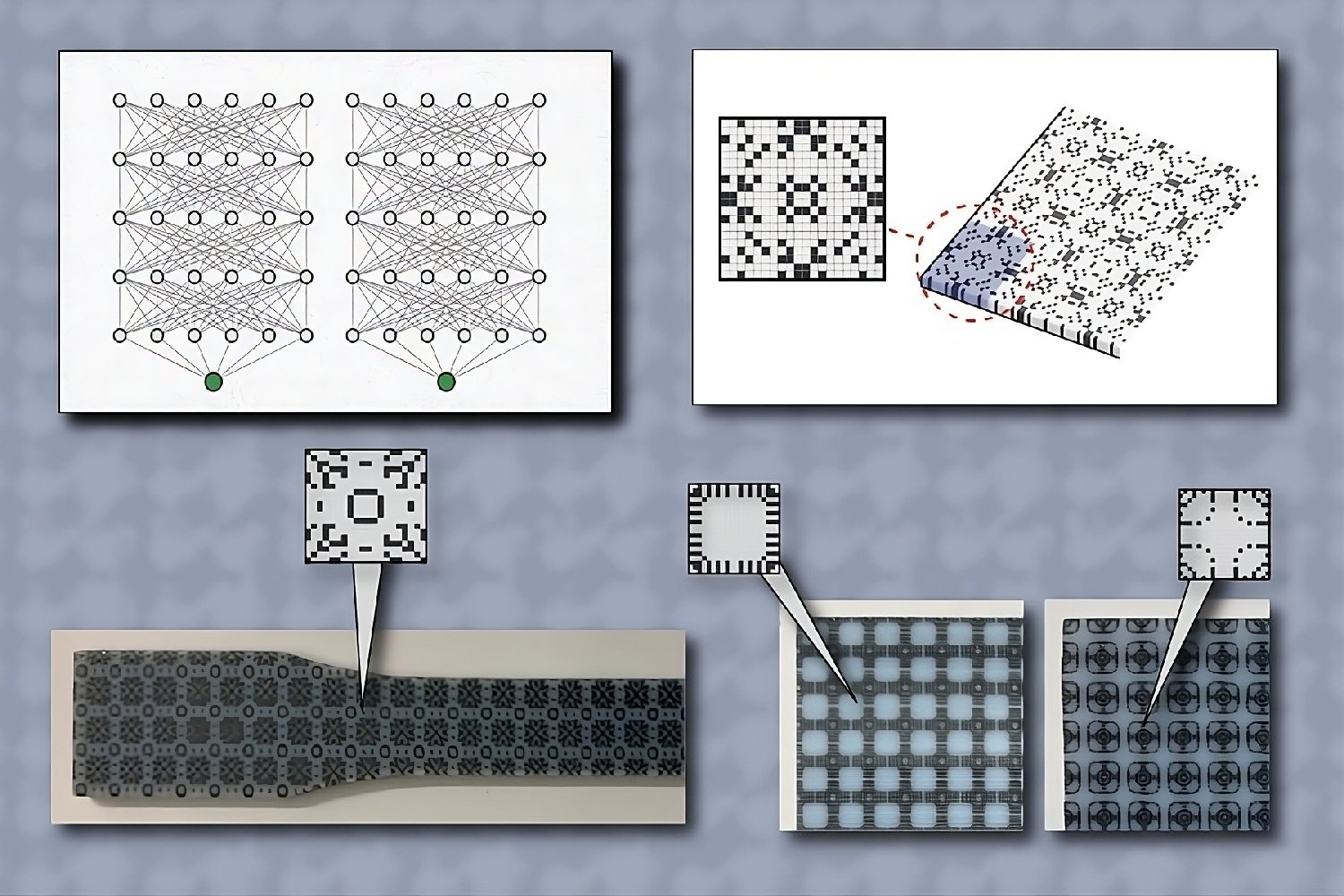

A key innovation of their strategy was the usage of neural networks as surrogate fashions for the simulations, decreasing the time and assets wanted for materials design. “This evolutionary algorithm, accelerated by neural networks, guides our exploration, permitting us to search out the best-performing samples effectively,” says Li.

Magical microstructures

The analysis staff began their course of by crafting 3D printed photopolymers, roughly the dimensions of a smartphone however slimmer, and including a small notch and a triangular lower to every. After a specialised ultraviolet gentle therapy, the samples have been evaluated utilizing an ordinary testing machine — the Instron 5984 — for tensile testing to gauge energy and suppleness.

Concurrently, the examine melded bodily trials with refined simulations. Utilizing a high-performance computing framework, the staff might predict and refine the fabric traits earlier than even creating them. The most important feat, they mentioned, was within the nuanced strategy of binding totally different supplies at a microscopic scale — a technique involving an intricate sample of minuscule droplets that fused inflexible and pliant substances, hanging the fitting stability between energy and suppleness. The simulations intently matched bodily testing outcomes, validating the general effectiveness.

Rounding the system out was their “Neural-Community Accelerated Multi-Goal Optimization” (NMO) algorithm, for navigating the complicated design panorama of microstructures, unveiling configurations that exhibited near-optimal mechanical attributes. The workflow operates like a self-correcting mechanism, frequently refining predictions to align nearer with actuality.

Nonetheless, the journey hasn’t been with out challenges. Li highlights the difficulties in sustaining consistency in 3D printing and integrating neural community predictions, simulations, and real-world experiments into an environment friendly pipeline.

As for the subsequent steps, the staff is concentrated on making the method extra usable and scalable. Li foresees a future the place labs are absolutely automated, minimizing human supervision and maximizing effectivity. “Our aim is to see the whole lot, from fabrication to testing and computation, automated in an built-in lab setup,” Li concludes.

Becoming a member of Li on the paper are senior writer and MIT Professor Wojciech Matusik, in addition to Pohang College of Science and Know-how Affiliate Professor Tae-Hyun Oh and MIT CSAIL associates Bolei Deng, a former postdoc and now assistant professor at Georgia Tech; Wan Shou, a former postdoc and now assistant professor at College of Arkansas; Yuanming Hu MS ’18 PhD ’21; Yiyue Luo MS ’20; and Liang Shi, an MIT graduate scholar in electrical engineering and laptop science. The group’s analysis was supported, partly, by Baden Aniline and Soda Manufacturing facility (BASF).

[ad_2]

Source link